All too often businesses get a bad rap being more focused on profits than people. When it comes to workplace safety there is a direct tie in between people and profits. Effective workplace safety programs require both time and money. Commitment levels range from “check the box, yes, we have a safety program,” to a top-down understanding that investment in safety is essential to a high-performance culture and conducting good business.

Given the constant pressure for performance and profits, even the most well-meaning management teams wrestle with the question, “Can we afford to go all in on safety?” The answer: “You can’t afford not to.”

The expense of not putting safety first is extreme. According to the 2017 Liberty Mutual Workplace Safety Index, the cost of disabling workplace injuries totaled $59.9 billion in 2017. While that’s down from $61.9 billion in 2016, it’s still a hefty chunk of change.

Why prioritize workplace safety?

There are multiple reasons why companies should implement and maintain workplace safety programs besides the expected benefits of accident prevention, reducing absenteeism and increasing productivity. These three facts rise to the top:

1) It’s the law – compliance with federal and state safety regulations is mandatory.

2) Even if it weren’t the law, maximizing safety in the workplace is simply the right thing to do.

3) Implementing job safety programs can actually improve the bottom line.

No, #3 is not a misprint. While these programs cost money to implement, safety and profitability are NOT mutually exclusive.

The good news is that you don’t have to be a multi-billion dollar company to afford or benefit from improving workplace safety. As a matter of fact, OSHA will even help you through their small business On-Site Consultation Program. In 2016, approximately 28,000 U.S. businesses – with, on average, fewer than 50 employees – availed themselves of this valuable program. Best of all: It’s free. For example:

- This small (19 employees) family business in Cheyenne, Wyoming specializes in customized packaging for clients all over the world. They began working with OSHA consultants eight years ago and have since reduced their Total Recordable Case rate (TRC) rate and Days Away from Work to 0.0. The result: In 2016 alone, they reduced their Worker’s Compensation premiums paid by $15,200, while greatly improving worker retention and morale.

- This family-owned 21-employee company headquartered in Unionville, Connecticut operates lumber yards and stores in Avon and Manchester, Connecticut, and West Springfield, Massachusetts. In 1988, an employee was severely injured using a saw. One of the consequences was that the company’s workers compensation insurance carrier to threaten to drop coverage if the company’s claim rate could not be reduced.

A lot has happened since – all of it good. After implementing stricter safety standards on their own, they partnered with OSHA to identify additional safety measures they could take. The result: In 2013, 2014, and 2015, their Total Recordable Case rate (TRC) rate and Days Away from Work was reduced to 0.0, greatly reducing on the job injury claims, medical care costs, and workdays lost.

Safety protects profitability.

From a dollars-and-cents standpoint, safety is critical to preserving a company’s profitability. In fact, manufacturers can save upwards of $4 to $6 for every $1 invested in safety programs.

Here are some ways safety and accident prevention programs reap rewards:

• Lowering insurance premiums due to lower risks

• Reducing workman’s compensation claims because of fewer on-the-job accidents and injuries

• Reducing the need to hire, train and pay replacements to fill in for injured workers, since fewer would be injured

• Eliminating fines and penalties by complying with OSHA regulations

• Increasing productivity by fostering a healthier workforce

• Reducing downtime and interruptions in delivery – leading to higher customer satisfaction

• Reducing the number of safety issues with equipment, which in turn results in fewer costly repairs and replacements

Safety makes dollars…and sense.

In addition to increasing profitability, it makes sense that well-executed workplace safety programs also deliver qualitative benefits. At the top of the list is boosting employee morale and loyalty. Let’s face it. Wouldn’t you be more motivated to work for a company that cares about you? Instead of looking for greener pastures, engaged employees are more likely to collaborate with project teams and contribute towards increasing productivity. They may also be more open to participating in other corporate programs that range of health and wellness fairs to philanthropic activities.

Get Them Involved.

Similar to other corporate initiatives, a safety program is most likely to succeed when employees are engaged right from the start. Safety improvements work well when the company solicits employee input on how to make their production processes safer.

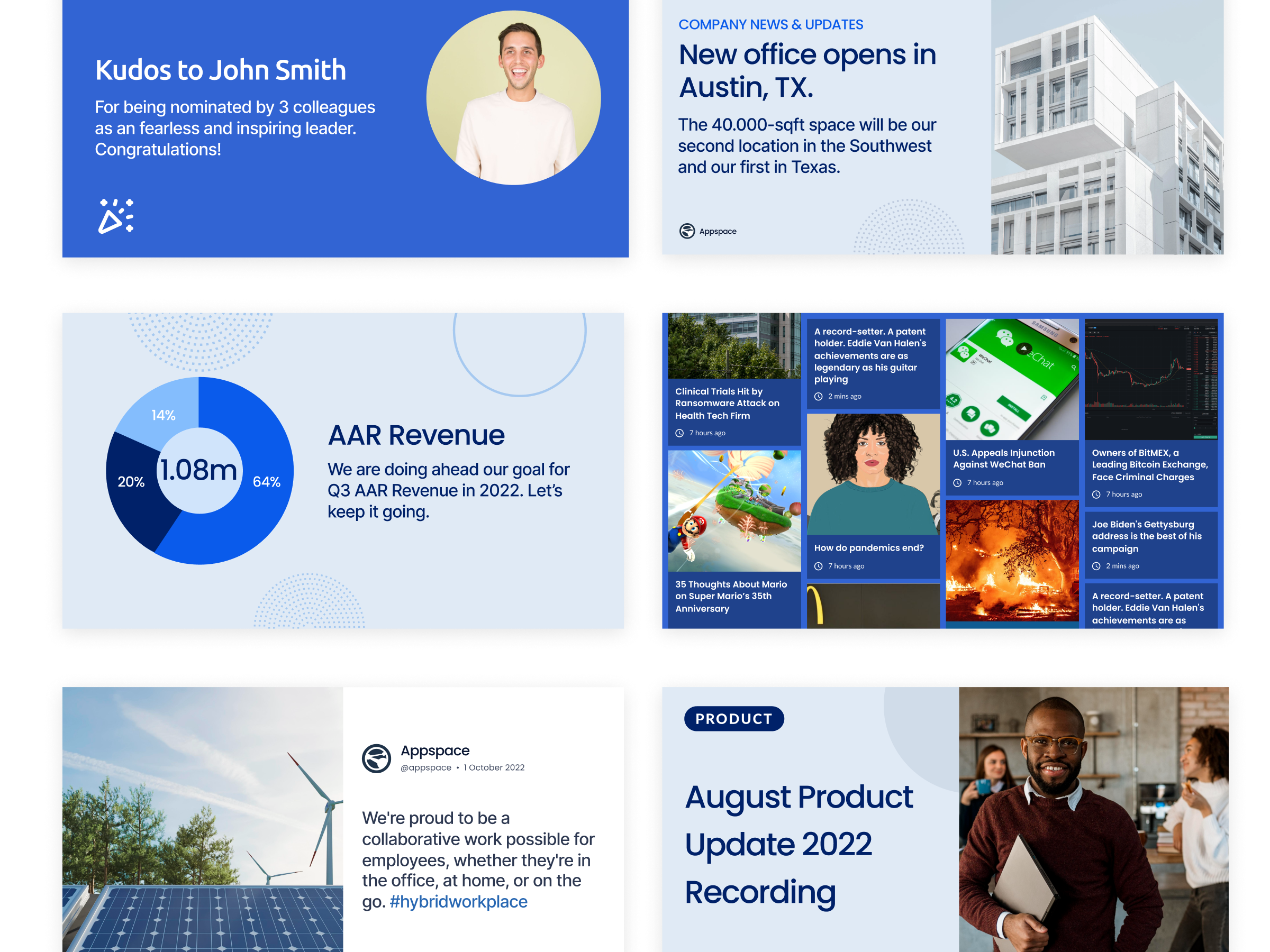

Workplace communication is key to enlisting employees’ support. Forming safety committees and posting safety tips on bulletin boards is a great start. And don’t forget to recognize employees for on and off-the-job safety by posting to your company’s social media channels. Using digital display signage is an ideal way to inform and motivate workers in the warehouse and on the shop floor.

Good Character.

Legendary UCLA basketball coach John Wooden once said: “The true test of someone’s character is what he does when no one is watching.” What if there were no OSHA, no state or federal workplace safety regulations, and no inspections? Would you still do everything in your power to make your workplace as safe as possible? Would you make safety an integral part of your company’s DNA? I firmly believe that a vast majority of companies would.

Putting safety first is not only good for the bottom line; it’s the right thing to do.